SHOTBLASTING AND / OR SHOT BLASTING PLANTS, WHAT ARE THEY AND WHAT DO THESE WORDS MEAN?

THE WORD SHOT BLASTING IS USED TO IDENTIFY A SYSTEM THAT, BY MEANS OF THE CENTRIFUGAL FORCE GENERATED BY AN ELECTRIC TURBINE,

PROJECTED METAL PARTICLES CALLED GRIT AGAINST A SURFACE (WORKPIECE TO BE TREATED) GENERATING A SURFACE TREATMENT OF: CLEANING,

ROUGHENING, HARDENING, THIS LAST TREATMENT IS CALLED PEENING OR SHOT-PEENING (THE DEGREE OF PEENING ALMEN IS MEASURED IN

UNITS OF MEASURE THAT SHOWS THE COVERAGE REFERRED TO A WELL-DEFINED SAMPLE)

THE FIELDS OF USE OF THE SHOT-BLASTING MACHINES ARE AMONG THE MOST VARIED DEPENDING ON THE INTEREST TO ONE OR MORE OF

THE OBTAINED RESULTS. SOME APPLICATION EXAMPLES OR WORK CONCERNED THE ACTION OF BLASTING ARE:

CORING OF CASTINGS, CLEANING CASTINGS DESCALING STEEL, PREPARATION OF METAL STRUCTURES BEFORE PAINTING AND / OR ZINC PLATING,

ANTIQUE SEMI-PRECIOUS STONES (HAMMERED EFFECT), SHOT PEENING OF GEAR CUTTING TOOLS AND SPRINGS, BLASTING OF LARGE

EARTH-MOVING MACHINES AND CARPENTRY OF ALL THE METAL STRUCTURES IN GENERAL THAT REQUIRE A GOOD SURFACE PREPARATION

PRIOR TO THE FINAL TREATMENT THAT IS LIQUID PAINTING / DUST, GUMMING AND / OR SPECIFIC TREATMENTS WITH CARRY-OVER OF MATERIALS.

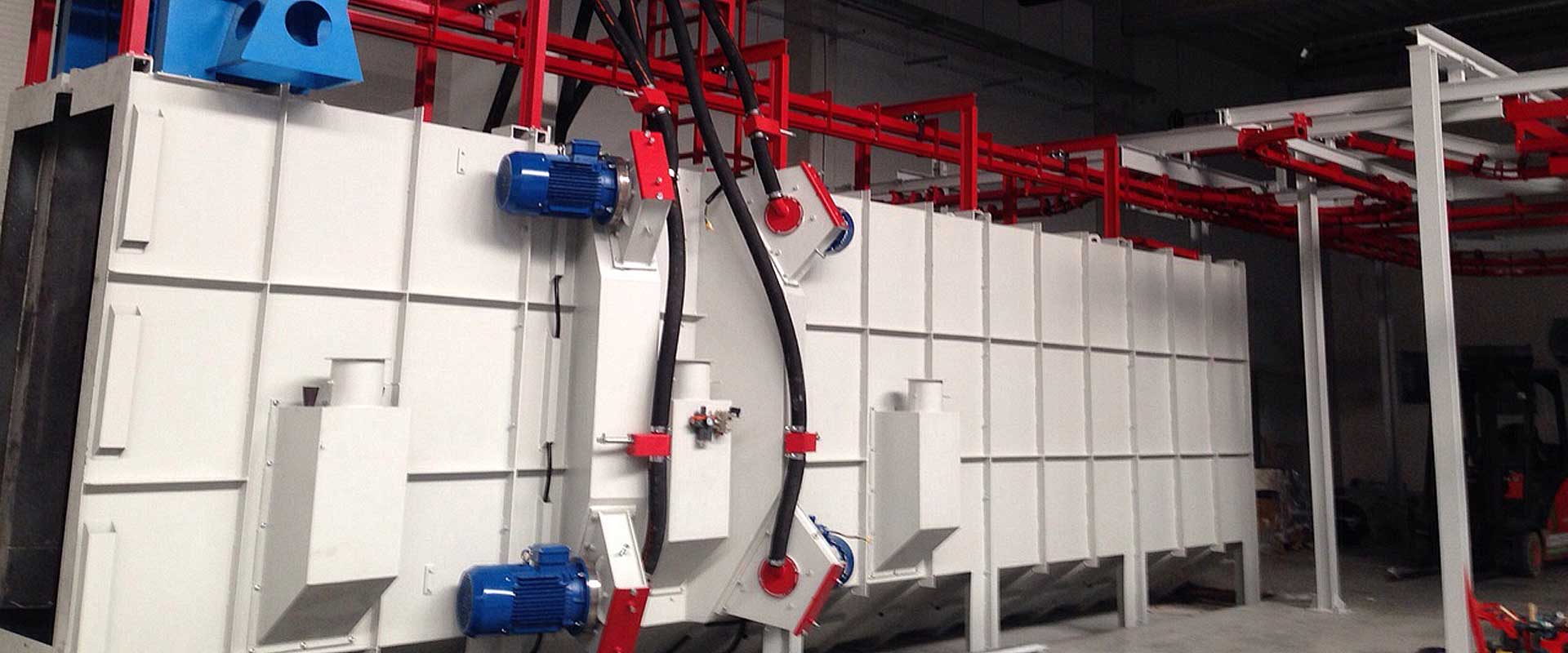

ADVANCED TECHNOLOGY SOLUTIONS

The high quality and the constant updating of know-how, have led BV SHOTBLASTING MACHINES to develop technologically

advanced solutions coming to install their own equipment in major world markets by tapping multiple industry sectors,

including: automotive, armaments, shipbuilding, railways, oil & gas, foundry, major structural works, mechanical precision.

BROCHURE

Download brochure BV Shotblasting Plants

SHOTBLASTING MACHINES USED AND REFURBISHED

BV shotblasting machines, in addition to the production of the new, has always available a wide range of shot blasting

equipment that are refurbished returning them in accordance with "CE" rules to the electrical and mechanical part components.